The Maker Movement

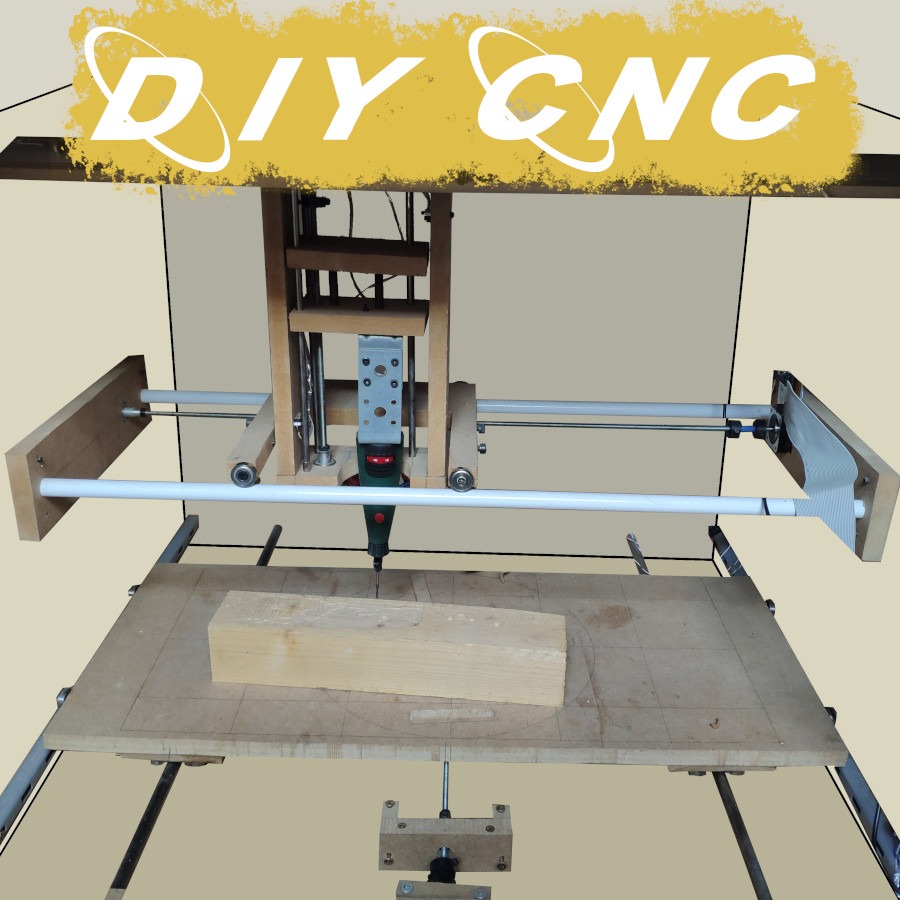

3D printers were becoming trendy but were still quite expensive in 2015. Rather than buy one, I decided to create my own CNC machine that could both cut and print.

The Vision

The goal was ambitious: a multi-purpose machine that could:

-

3D print using a standard extruder

-

Mill and cut materials using a spindle attachment

-

Engrave detailed patterns

The Reality

I didn't fully achieve the project due to time constraints and because 3D printers became super cheap soon after I started. By the time I was ready to finish, you could buy a decent printer for less than my materials cost.

What I Learned

Despite not completing the project, I gained invaluable experience:

-

Stepper motor control - understanding how to precisely move axes

-

G-code programming - the language of CNC machines

-

Mechanical design - creating rigid, accurate linear motion systems

-

Electronics integration - connecting motors, drivers, and controllers

The Lesson

Sometimes unfinished projects teach you more than finished ones. The knowledge I gained about CNC systems would prove useful in countless future projects, from designing parts for robots to understanding how prosthetic components could be manufactured.